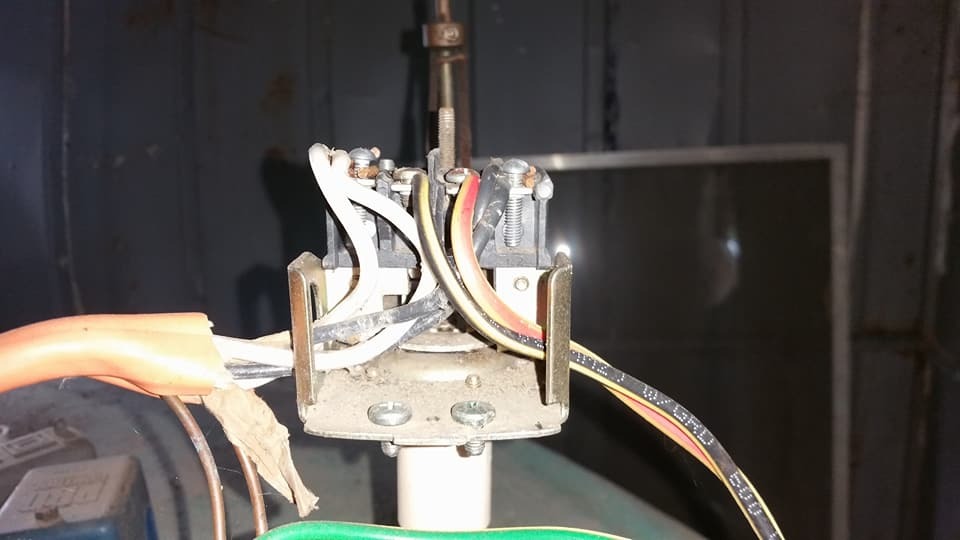

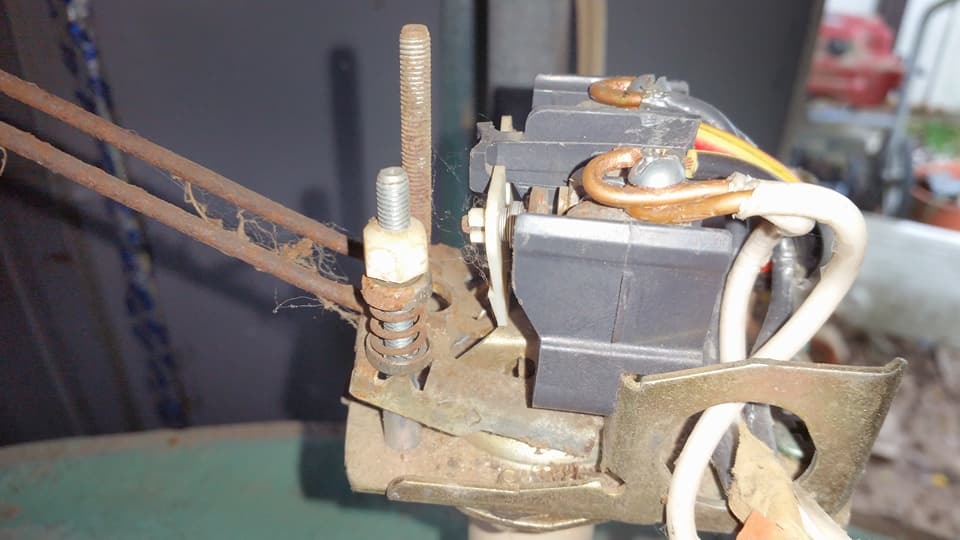

Ok. So, remember this thing I mentioned that sometimes doesn't sense the float level? In the past it would stay on when the float was up but lately it has not been turning on when the float gets low.

Here is a more recent photo with the cap on it.

I don't know if the arm itself is sticking or if the stuff inside the box just isn't detecting the movements or what. But in the past week I've had to go outside and jiggle the float thing to make the pump turn back on because the tank was empty and it didn't seem to detect that the float was down. The jet pump was still going trying to push water, but there was no water to push.

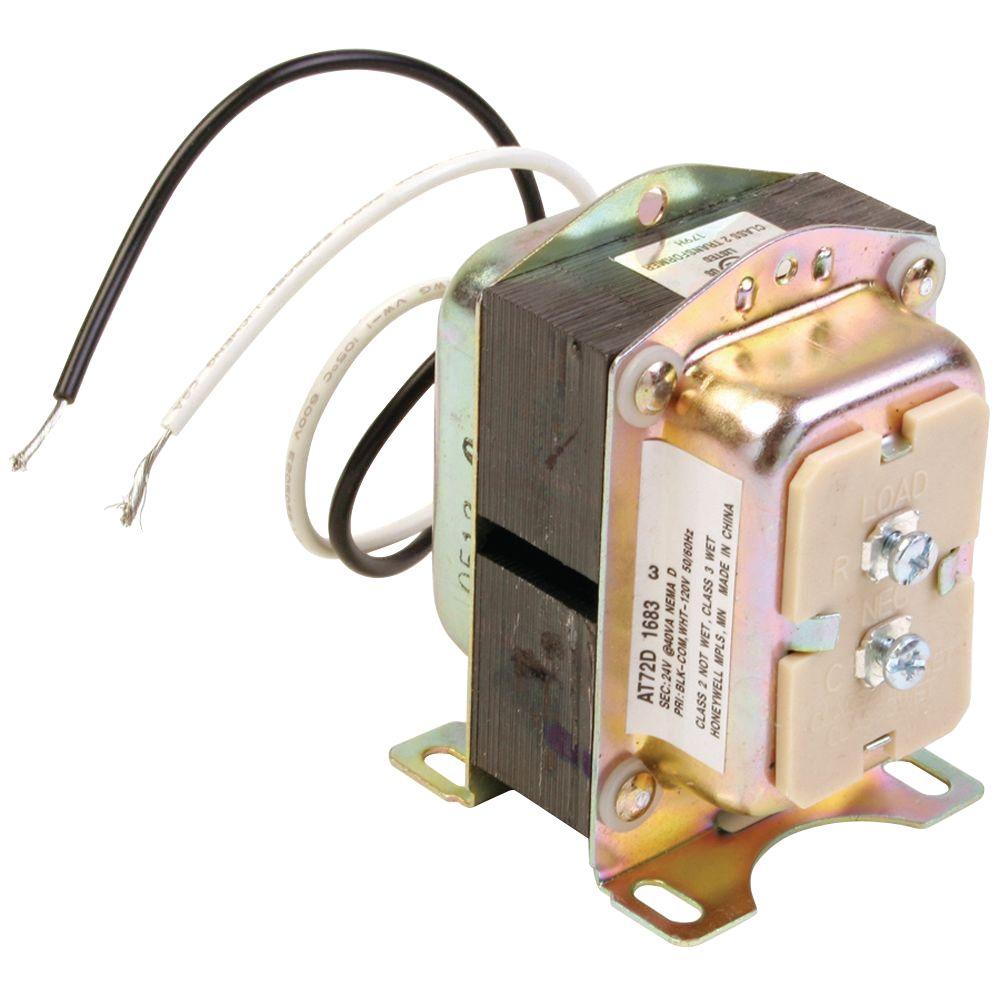

I don't even know what the mechanism is called, but I would like to replace it-- preferably with something more efficient. Any ideas? Links to products and info on how to install it would be very helpful and greatly appreciated.

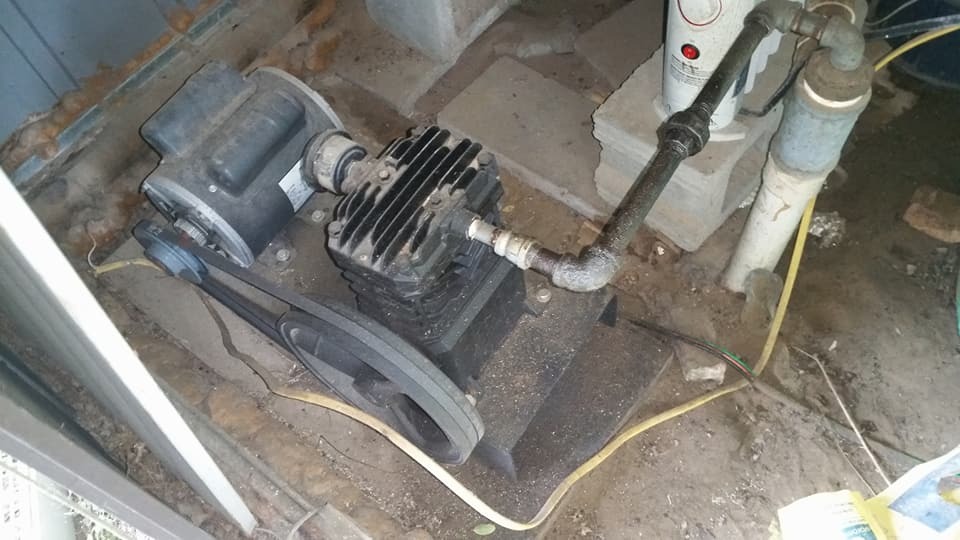

I don't want my jet pump to burn out because of this issue.

I know in the past solenoid valves were mentioned, but I never did find something that looked like it would work (but maybe it's just my lack of understanding of how the things work).

Here is a more recent photo with the cap on it.

I don't know if the arm itself is sticking or if the stuff inside the box just isn't detecting the movements or what. But in the past week I've had to go outside and jiggle the float thing to make the pump turn back on because the tank was empty and it didn't seem to detect that the float was down. The jet pump was still going trying to push water, but there was no water to push.

I don't even know what the mechanism is called, but I would like to replace it-- preferably with something more efficient. Any ideas? Links to products and info on how to install it would be very helpful and greatly appreciated.

I don't want my jet pump to burn out because of this issue.

I know in the past solenoid valves were mentioned, but I never did find something that looked like it would work (but maybe it's just my lack of understanding of how the things work).