It looks like you have a LOT of work ahead of you. The first priority is to make sure you don't have sewer gases coming up in to your home as they are dangerous. Aside from the stench, the methane can kill you or at the very least make you very ill. If you are feeling ill or more tired than usual, it could be from the sewer gases. I would highly recommend fixing the washing machine standpipe asap or at least capping it off when not in use until you can fix it properly. After flushing toilets & hearing gurgling noises, run water slowly in all of the sinks to fill up the traps (I have to do this in my home bc my sinks are S-trapped). The shower (if that is a shower) needs to have a plug or something put in the drain when not in use to keep sewer gases from coming up).

S-traps used to be allowed in older homes before the plumbing code improved & the role of air pressure was better understood. Some stores still sell S-traps even though they are not allowed by code.

I will point out that AAVs might not work if you don't have any actual vents going out through the roof. You really do need at least one atmospheric vent. You need to have both positive and negative air pressure- air behind and ahead of the water to allow it to flow or it creates a vacuum. AAVs only work for the negative air pressure. There is something called a PAPA for positive air pressure. The easiest way to see how the vacuum works is to take a straw and put it in liquid, put your thumb on the top to block airflow and lift it up. The water stays in the straw until you remove your thumb- that's because air can't get behind the water to allow it to flow down. Drains work by gravity but vacuums can interfere with that.

It would also help if you could try to provide drawings/diagrams of the layout and where the plumbing is in relation to the house/rooms etc. You can get a free version of Google Sketchup that lets you do precise measurements to draw out the floorplan and you can use the push/pull tool to raise the walls & make it 3D. You can screenshot it and put it in MSPaint to draw lines where the plumbing is if the 3D model stuff is too much of a pain to use.

It's going to take time and $, but people here are friendly & will do their best to help you through it. If you find yourself unsure about something, don't hesitate to ask. Don't push yourself too hard and you can tackle things a little at a time so you don't get overwhelmed.

While you are at it, I would also recommend that you take a look at your electrical to see what your wiring situations is so you don't end up with an electrical fire. There is a sister site to this one called

houserepairtalk where you can get answers to things about roofing, structure, electrical, etc. Many of the people here also post over there.

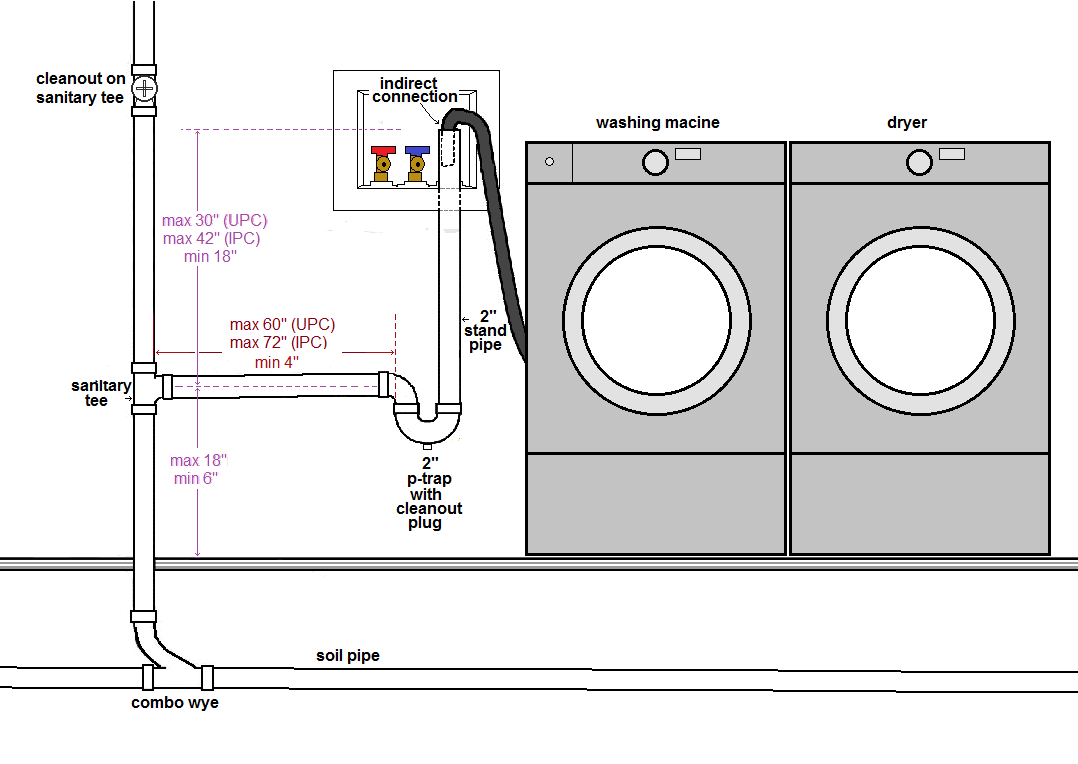

It looks like you live in Pennsylvania? I believe you'd be under IPC (if that helps any while looking up code).