Can I run a 3" waste line through existing 2" X 8" floor joist using some kind of support? I want to renovate my upstairs bath, which sits on 2x8 joists at 16" o.c. I'd also like to swap the position / sides with its existing location to the other side of the room. Doing so I would have to notch the existing 2" X 8" floor joist to accommodate the new 3" waste line.

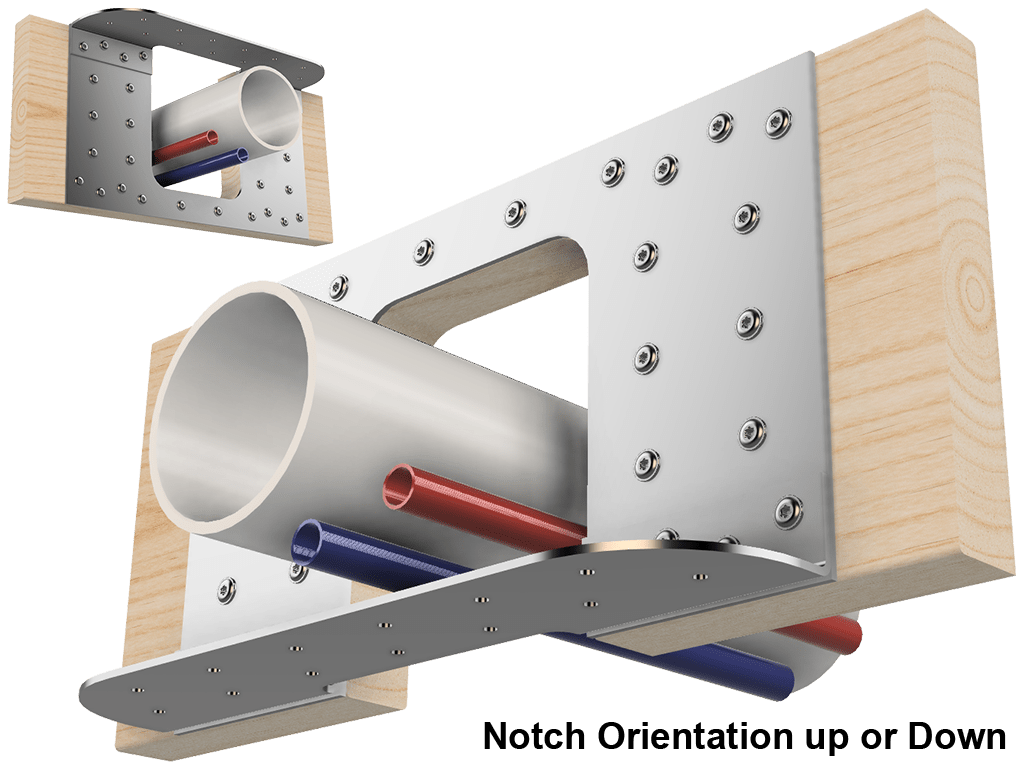

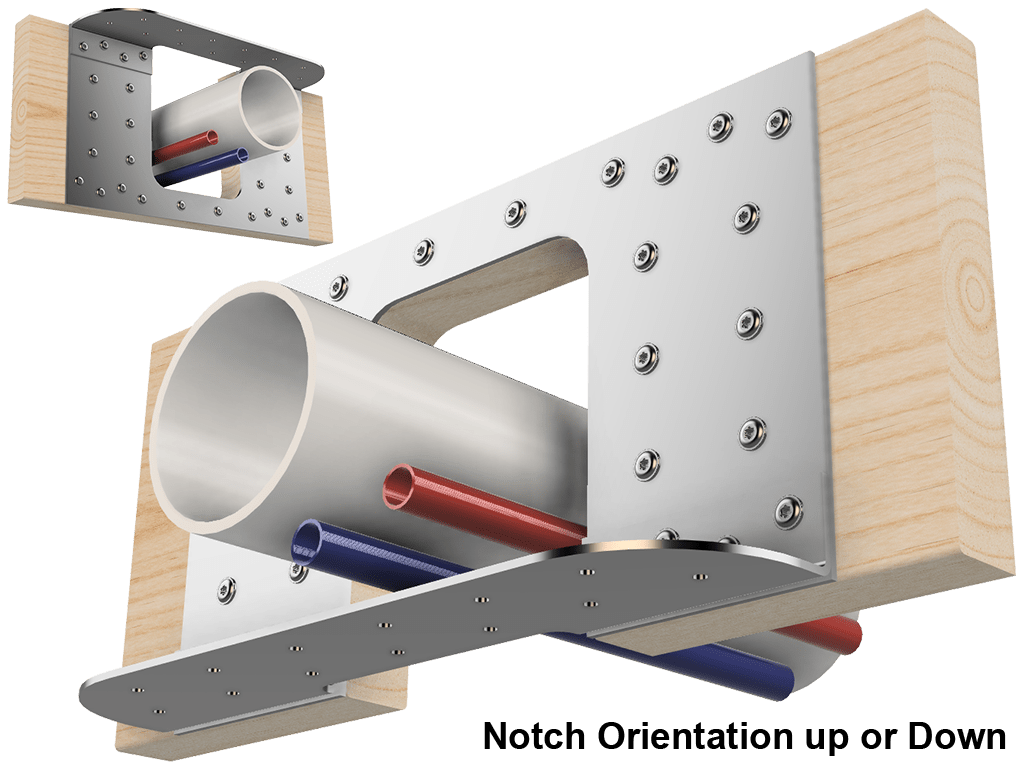

I've see they make joist notch repair kits from steel plate designed to restore the strength of the floor joists from over cut. They are expensive ($80.00 ea) are there other ways to reinforce the joist?

It would be difficult to sister another 2" X 8" up against the existing joist without a lot of additional work. The new line would be 20" away from the end of the joist at the outside wall.

Also with is the minimum fall for a toilet waste line before I have trouble?

I've see they make joist notch repair kits from steel plate designed to restore the strength of the floor joists from over cut. They are expensive ($80.00 ea) are there other ways to reinforce the joist?

It would be difficult to sister another 2" X 8" up against the existing joist without a lot of additional work. The new line would be 20" away from the end of the joist at the outside wall.

Also with is the minimum fall for a toilet waste line before I have trouble?

Last edited: