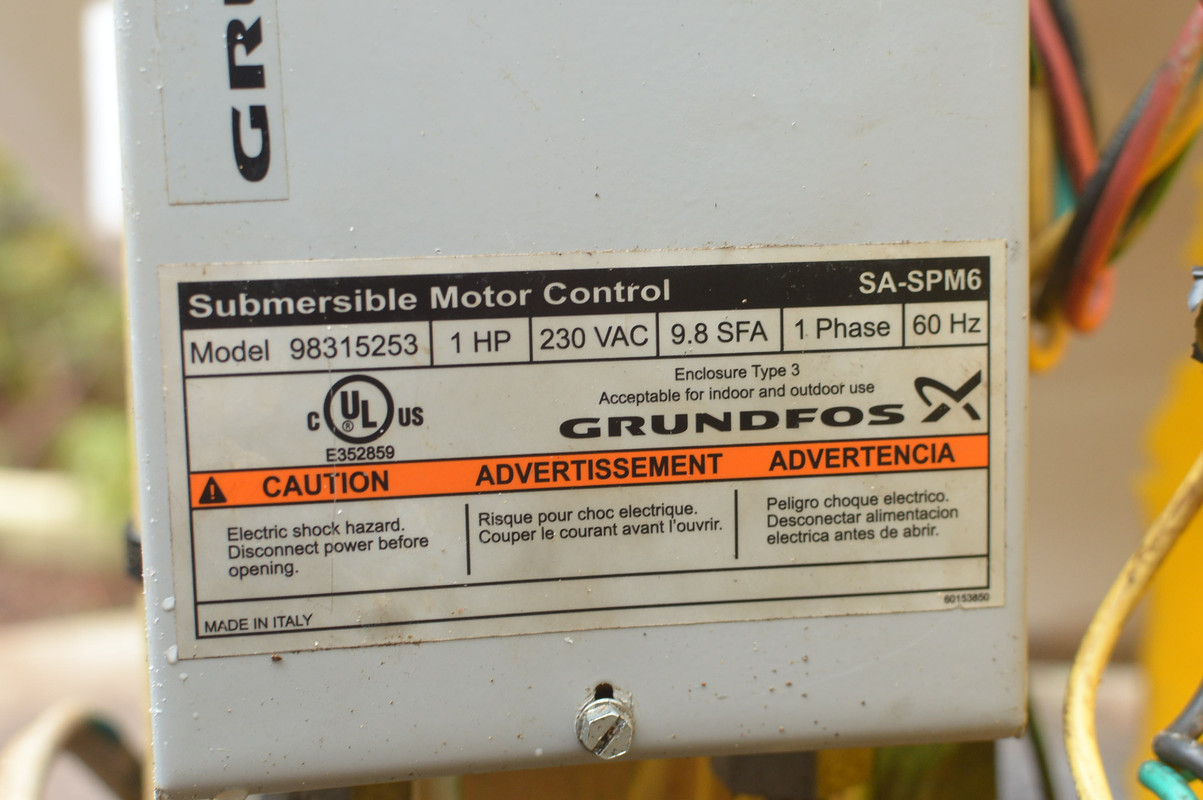

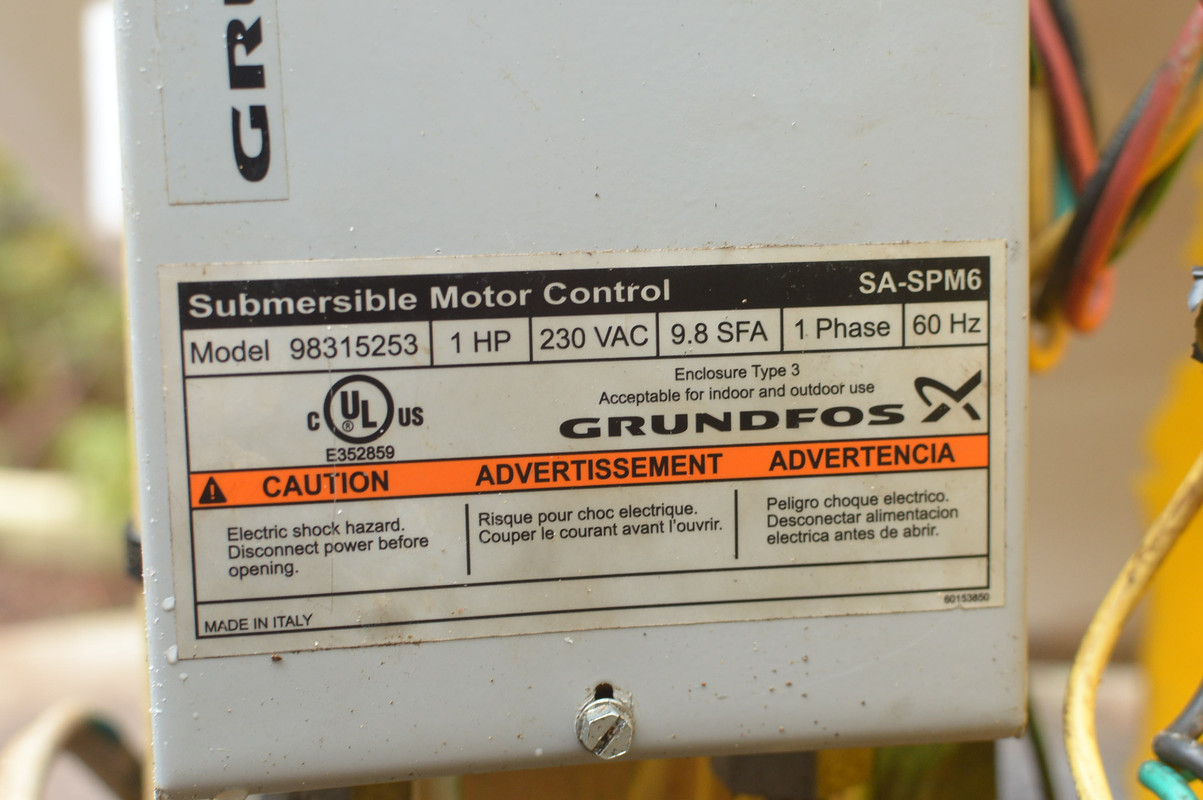

This is my pump controller I do not know what kind of pump it has. It is a shallow well. :

While I can find capacitors in this range, I am having a harder time finding one with a resistor across each pole like this one does (however, it's not shown in the picture. I forgot to take one before I put it back together).

The gallery below shows the relay inscribed: RVA2AL3L L524 35A 400VAC

https://postimg.cc/gallery/G497k8

Any help or ideas to look would be wonderful!

Thank

While I can find capacitors in this range, I am having a harder time finding one with a resistor across each pole like this one does (however, it's not shown in the picture. I forgot to take one before I put it back together).

The gallery below shows the relay inscribed: RVA2AL3L L524 35A 400VAC

https://postimg.cc/gallery/G497k8

Any help or ideas to look would be wonderful!

Thank