Hello forum,

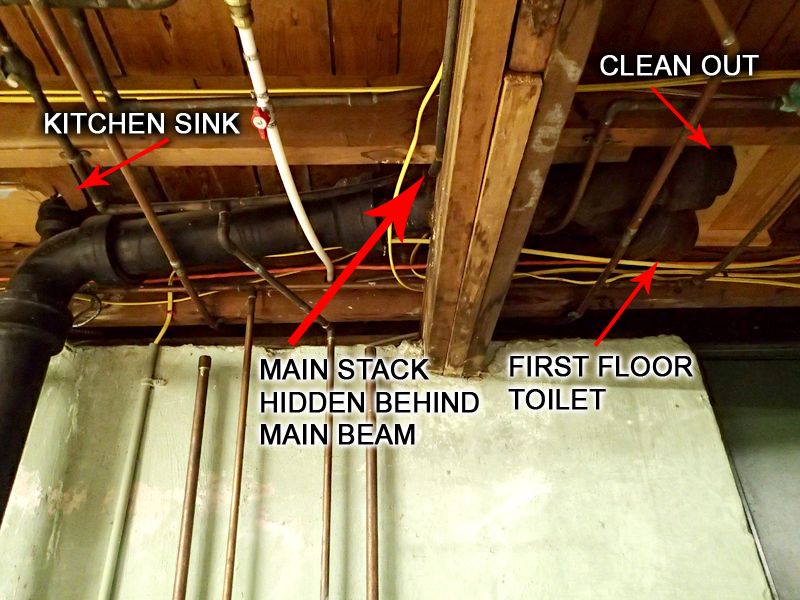

I'm considering taking on a rather large project here and I'm wondering if it's possible to do this on my own. What I have is a 1948 Cape with 1 full bath (upstairs) and 1/2 bath downstairs. In order to get to the stack, I will have to demo 1 wall in the 1/2 bath downstairs, and the upstairs full bath. The full bath is directly on top of the 1/2 bath, with the main stack running straight up, right behind the toilets. I'm not planning on tearing up the basement floor at this point, so the PVC would tie in just above the basement floor.

Most of the issues I'm having at this point are coming from the full bath on the second floor. The shower drain tends to back up quite often. I've snaked it out several times, and that will be good for a few months, then it starts to back up (usually with hair). The sink has the same problem, and neither of these are properly vented. The sink makes a terrible bubbling/gurgling noise when draining as it gasps for air.

So, from the roof I want to remove all the cast iron, and replace with PVC all the way down to the basement where it ties into the cast just above the floor. While the wall is opened up, I'm going to replace the copper with PEX. There was a galvanized nipple for the upstairs bathroom sink that already leaked and destroyed the wall behind the vanity. That post is here:

Leaking Sink Supply Lines

I think I can do all the PEX, but I'm wondering if the cast iron replacement is too much for me to handle. I wouldn't mind doing all the demo work and have a licensed plumber come in and do all the PVC work, but I have yet to find someone I trust around here (NH). Any thoughts? I appreciate any direction/advice.

I'm considering taking on a rather large project here and I'm wondering if it's possible to do this on my own. What I have is a 1948 Cape with 1 full bath (upstairs) and 1/2 bath downstairs. In order to get to the stack, I will have to demo 1 wall in the 1/2 bath downstairs, and the upstairs full bath. The full bath is directly on top of the 1/2 bath, with the main stack running straight up, right behind the toilets. I'm not planning on tearing up the basement floor at this point, so the PVC would tie in just above the basement floor.

Most of the issues I'm having at this point are coming from the full bath on the second floor. The shower drain tends to back up quite often. I've snaked it out several times, and that will be good for a few months, then it starts to back up (usually with hair). The sink has the same problem, and neither of these are properly vented. The sink makes a terrible bubbling/gurgling noise when draining as it gasps for air.

So, from the roof I want to remove all the cast iron, and replace with PVC all the way down to the basement where it ties into the cast just above the floor. While the wall is opened up, I'm going to replace the copper with PEX. There was a galvanized nipple for the upstairs bathroom sink that already leaked and destroyed the wall behind the vanity. That post is here:

Leaking Sink Supply Lines

I think I can do all the PEX, but I'm wondering if the cast iron replacement is too much for me to handle. I wouldn't mind doing all the demo work and have a licensed plumber come in and do all the PVC work, but I have yet to find someone I trust around here (NH). Any thoughts? I appreciate any direction/advice.