I bought a ‘renovated’ house that was never quite finished. And all of the renovations were done by obviously less-than-skilled labourers (I work in construction but mainly hvac).

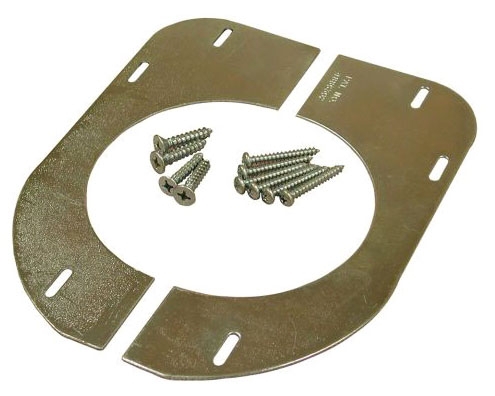

anyways, here I am 3 years later and one of our toilets has started shifting and wobbling. It moved to the point where you can see a void underneath. you can see where whatever caulking they used finally went bad. So I crawled under my house to see what was going on. Apparently, when the remodeled that bathroom, they cut a 5 or 6 inch hole through the sub flooring and then hammered out a same sized ‘hole’ in the tile, ran the 3 inch drain pipe up, stuck the flange on the pipe, then stuck the toilet on the flange. So the flange is just floating in thin air on the pipe and the toilet is just sitting on the tile. Is there a way to get something in there that I can bolt to without taking up the tile and replacing part of the subfloor? Thank you all

anyways, here I am 3 years later and one of our toilets has started shifting and wobbling. It moved to the point where you can see a void underneath. you can see where whatever caulking they used finally went bad. So I crawled under my house to see what was going on. Apparently, when the remodeled that bathroom, they cut a 5 or 6 inch hole through the sub flooring and then hammered out a same sized ‘hole’ in the tile, ran the 3 inch drain pipe up, stuck the flange on the pipe, then stuck the toilet on the flange. So the flange is just floating in thin air on the pipe and the toilet is just sitting on the tile. Is there a way to get something in there that I can bolt to without taking up the tile and replacing part of the subfloor? Thank you all