Hello,

I had a water heater tank installed in December 2017 after the old one went bad.

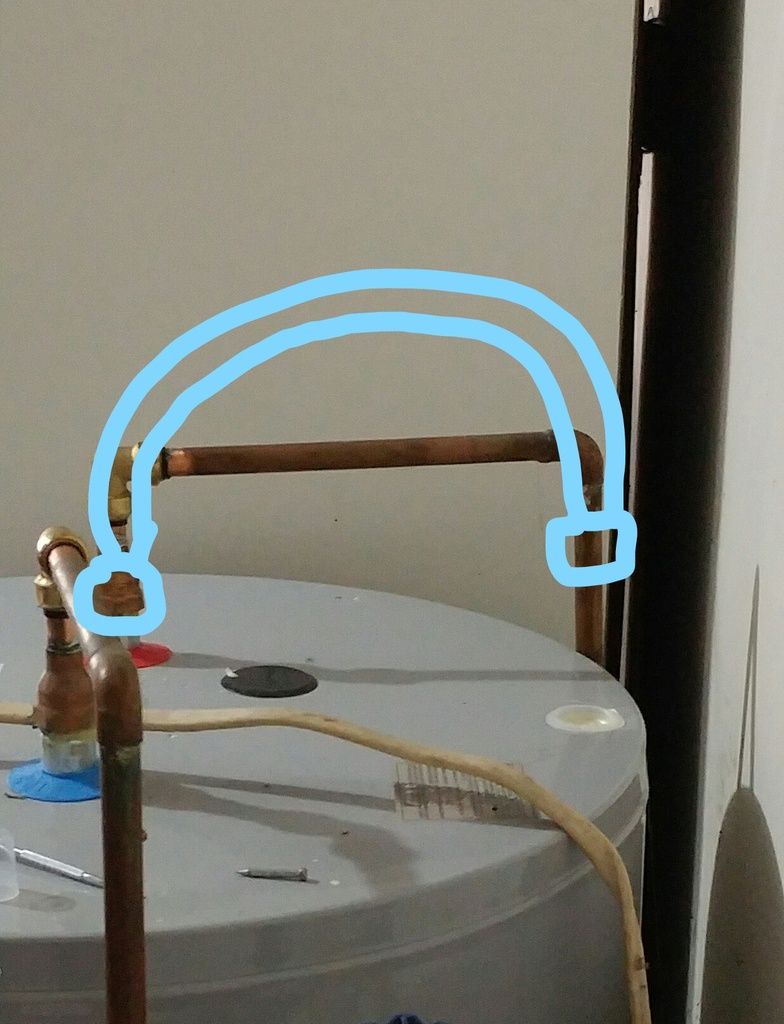

There is now a slow drip at the top joint for the hot water pipe (joint coming out of the tank).

To repair the slow drip can I just use JB Weld Epoxy putty and wrap it around the side of the joint that's leaking and be done with this?

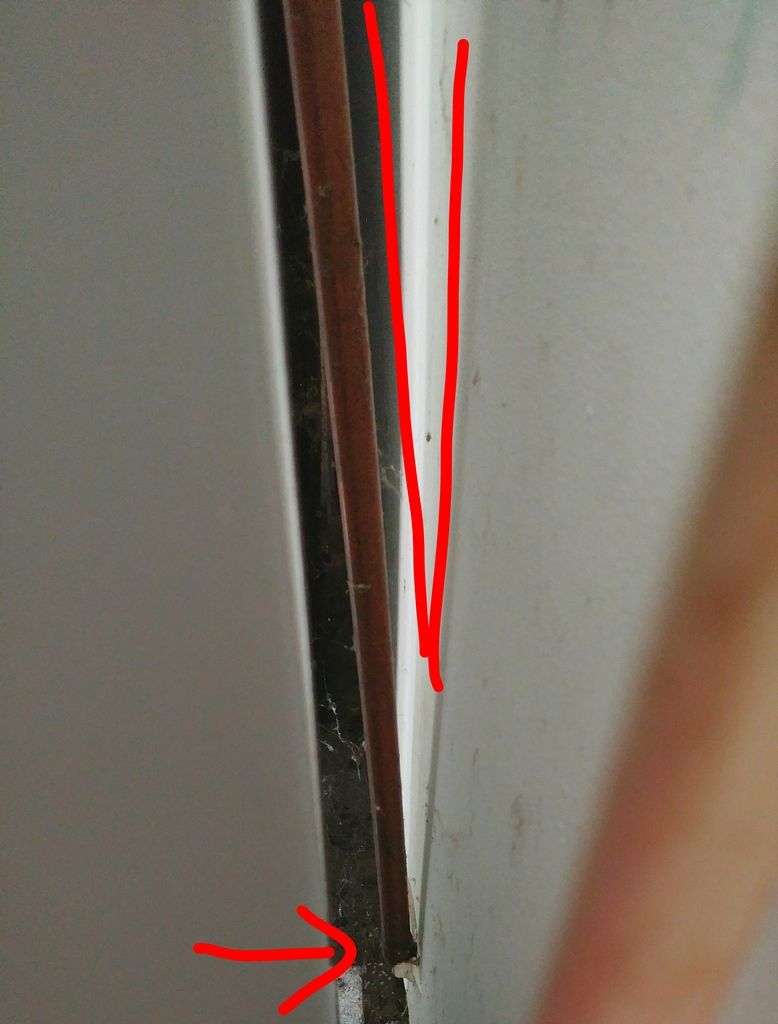

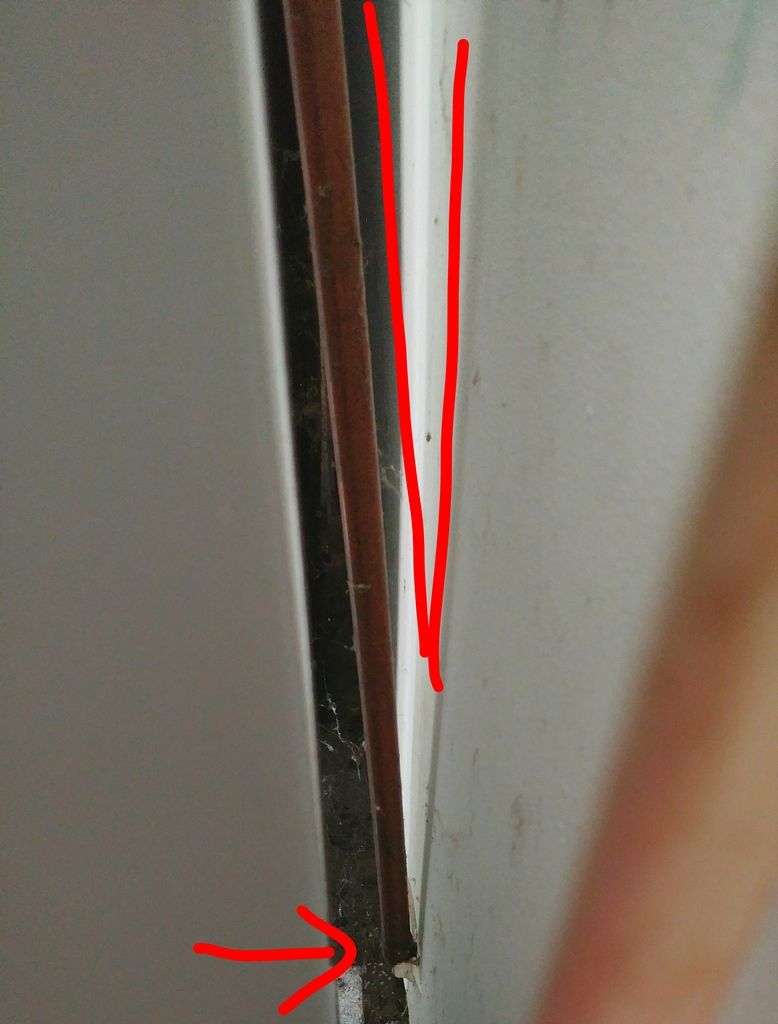

Just by looking at hot water pipe, you can can see that the plumber did not take the time to make this pipe go flush with the wall and it pulls away and separates a good 4 inches from the wall at the top.

The bottom joint at the wall may be under stress from being extended more than 90 degrees? This does not look good, but I am not sure if this can be acceptable and I should just not worry about it.

Should I be concerned about the way the hot water pipe is being pulled away from the wall or just repair the leak at the top joint and be done?

Any advise is much appreciated.

Here are some pics

I had a water heater tank installed in December 2017 after the old one went bad.

There is now a slow drip at the top joint for the hot water pipe (joint coming out of the tank).

To repair the slow drip can I just use JB Weld Epoxy putty and wrap it around the side of the joint that's leaking and be done with this?

Just by looking at hot water pipe, you can can see that the plumber did not take the time to make this pipe go flush with the wall and it pulls away and separates a good 4 inches from the wall at the top.

The bottom joint at the wall may be under stress from being extended more than 90 degrees? This does not look good, but I am not sure if this can be acceptable and I should just not worry about it.

Should I be concerned about the way the hot water pipe is being pulled away from the wall or just repair the leak at the top joint and be done?

Any advise is much appreciated.

Here are some pics