EliG

Member

Hi,

I have an elongated offset flange that looks very similar to this one:

http://www.canplas.com/product_category/3-or-4-offset-closet-flange/

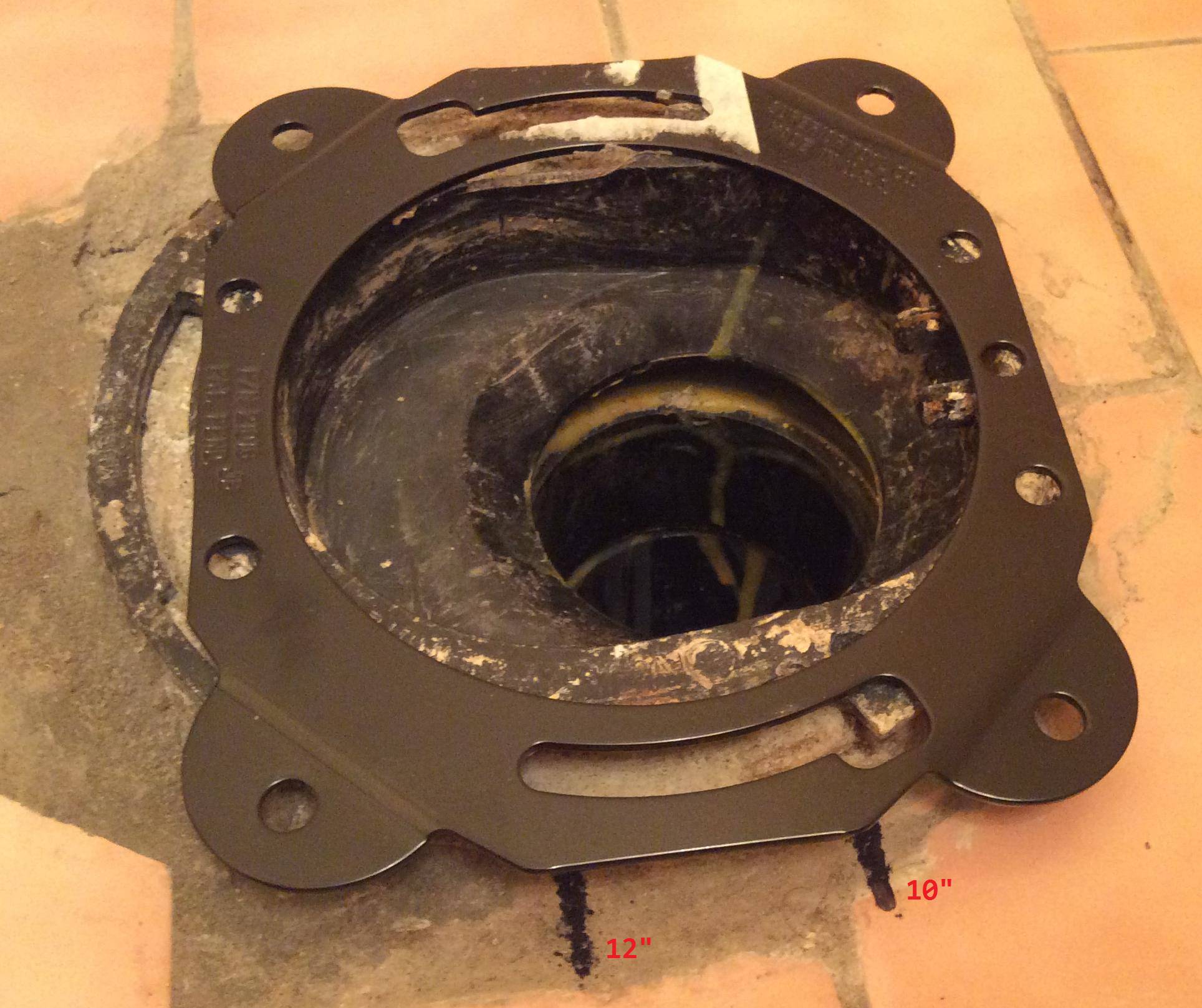

The flange sits on top of a concrete subfloor and is glued to the drain pipe.

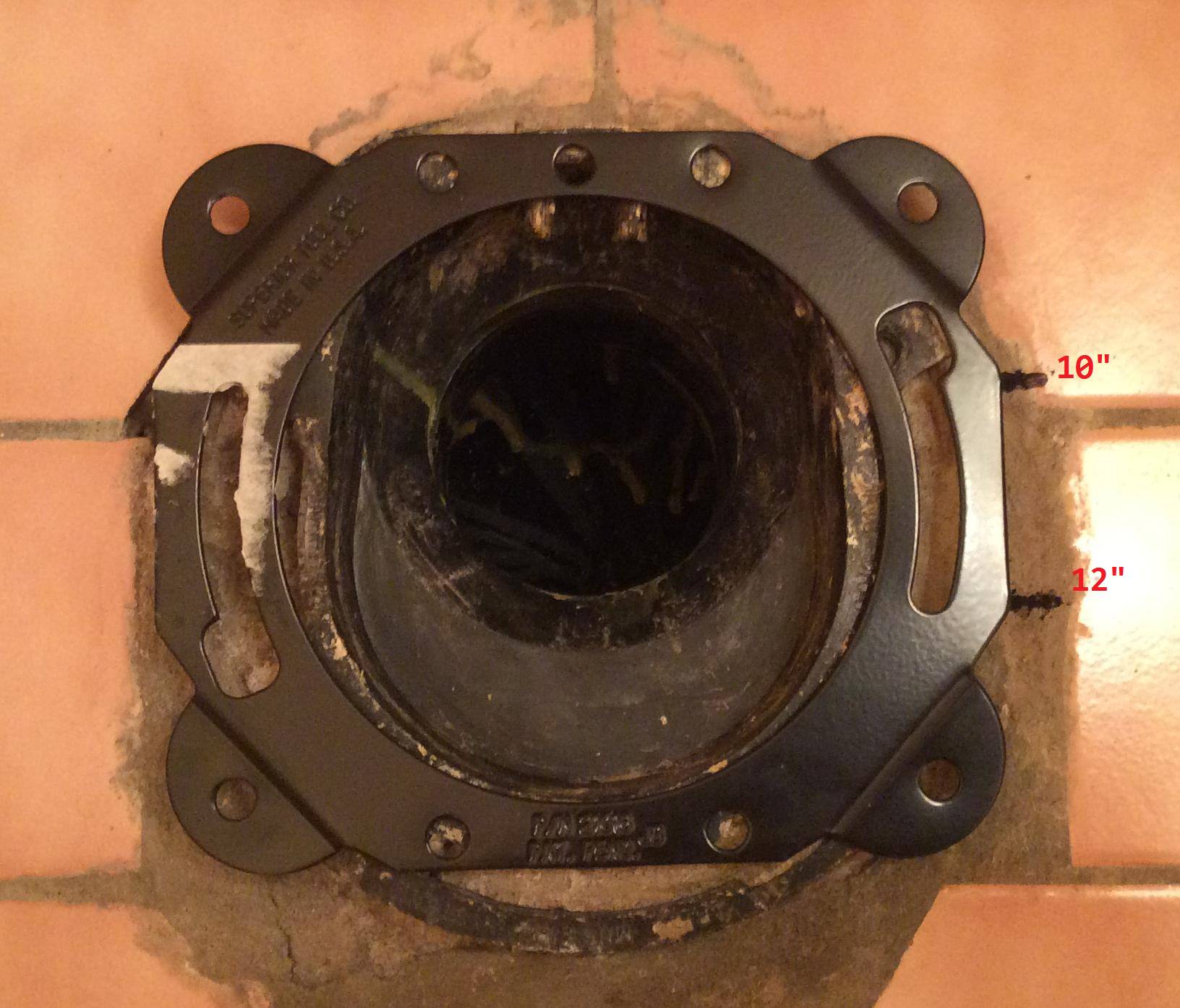

Flange wings are broken on both sides, as you can see in the pictures.

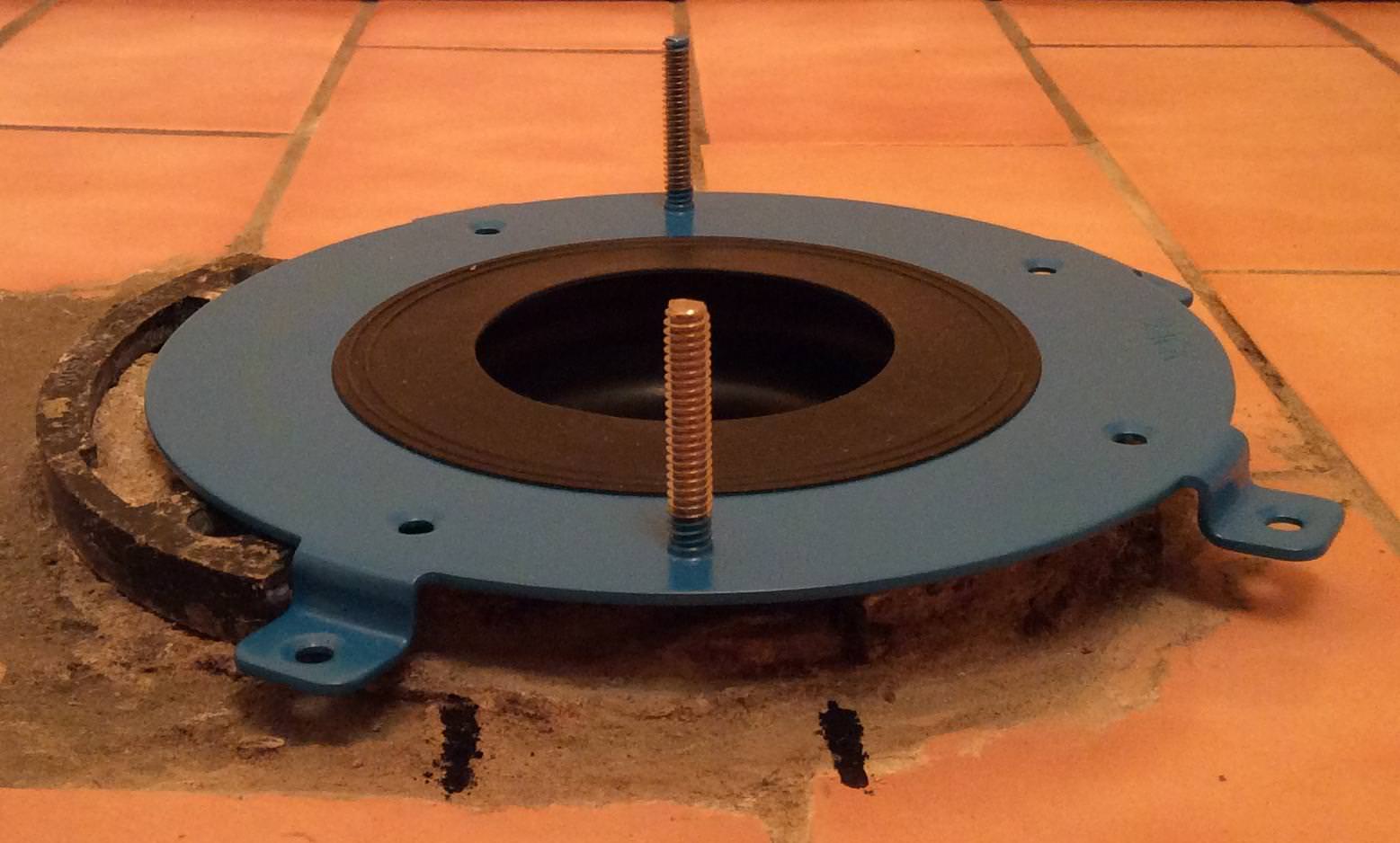

I can chip away concrete around the flange to create some space underneath it. Then put a repair kit in place.

The question is, what kind of repair kit? I couldn't find a repair kit made for the elongated offset flange.

Any suggestions?

I have an elongated offset flange that looks very similar to this one:

http://www.canplas.com/product_category/3-or-4-offset-closet-flange/

The flange sits on top of a concrete subfloor and is glued to the drain pipe.

Flange wings are broken on both sides, as you can see in the pictures.

I can chip away concrete around the flange to create some space underneath it. Then put a repair kit in place.

The question is, what kind of repair kit? I couldn't find a repair kit made for the elongated offset flange.

Any suggestions?

Last edited: