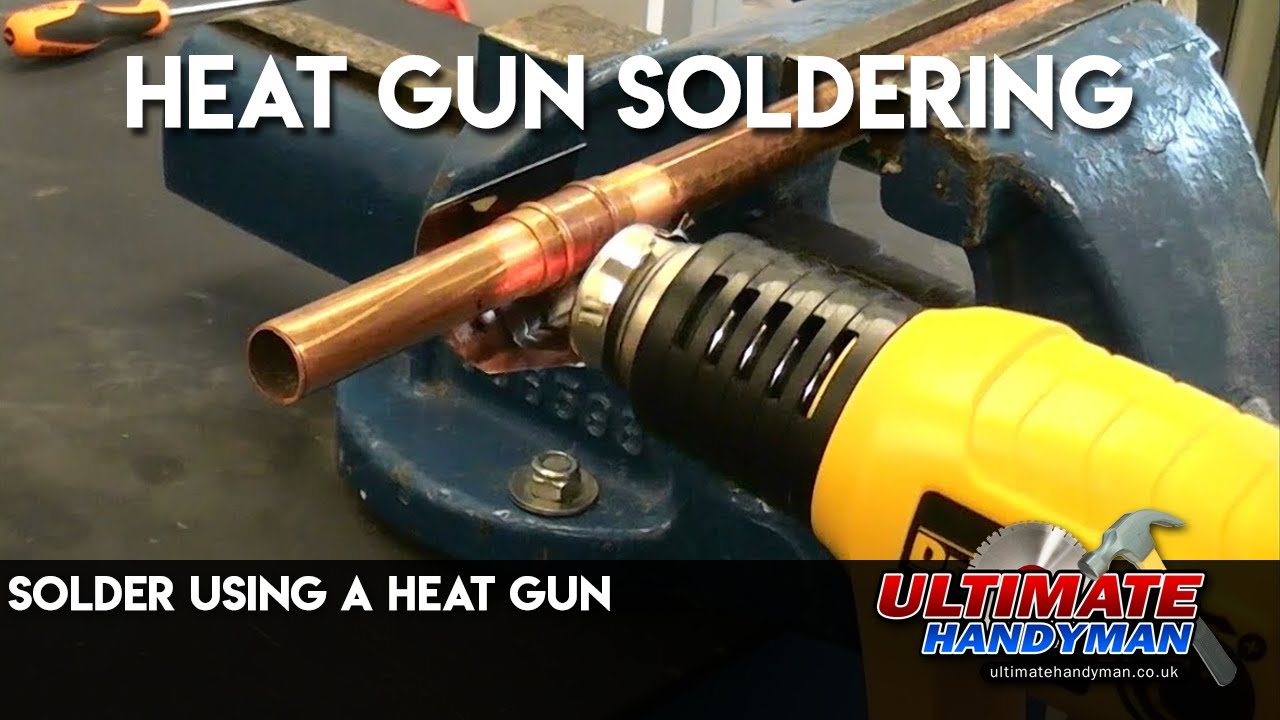

Pre-Soldered Fittings use an alloy of solder that melts at a lower temperature than standard solder. Since a typical electric heat gun supplies much less heat than a torch, to get the job done in a reasonable time, the heat gun demonstrator chose to use a Pre-Soldered Fitting.

The merits of such fittings are debatable, (and that discussion deserves a thread of its own), but I wonder if those who had trouble with Pre-Soldered Fittings hadn't yet gotten the hang of them. With a

Pre-Soldered Fitting, you heat the pipe more than the fitting. That's the opposite of the usual technique.

The other issue is the brass you asked about. While brasss affinity to copper (actually

brass is an alloy of copper and zinc) presents no problem, the thickness of the brass fitting may. Often a brass fitting is much thicker than the copper pipe it joins to. The thicker a fitting, the more heat it requires during the soldering process, and the weak electric heat gun may tax your patience.

You might consider practicing a little on some scrap pipe and a few extra fittings. Before you do your actual project, you should be confident in your own ability to succeed.

I don't know what of your situation makes you want to avoid the flame, but I assume it's a legitimate concern. If there's flammable material in range, get it wet first, and protectively cover it with something. A precautionary water hose wouldnt be a bad idea too.

If you really want to be cool, get a 5 kilowatt power supply, and learn [ame="https://www.youtube.com/watch?v=FMVqsSNO07g"]inductive soldering[/ame].