helloWorld

New Member

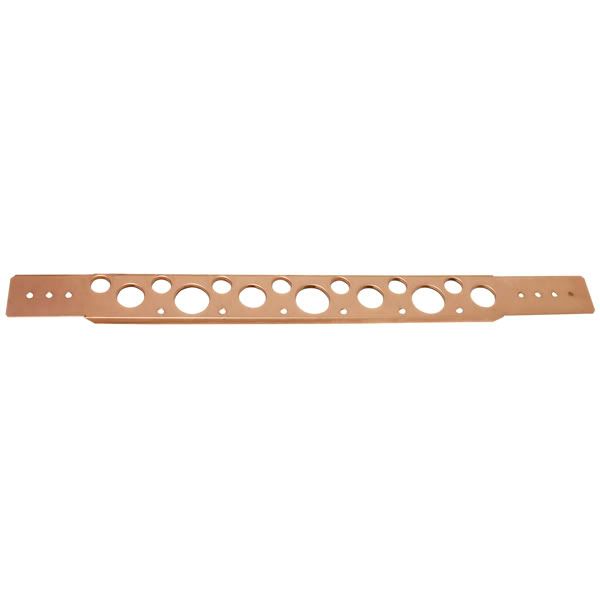

Hired a local plumbing company to replace the kitchen sink hot and cold stub-outs, move the drain and provide a cold water line for the refrigerator.

The result does not look professional at all to me. Any opinions?

The result does not look professional at all to me. Any opinions?